Accuracy is everything and in the fast food world - timing also. Instead, a sauce filling machine can become the turning point of your business bottling operations with various advantages that will alone create an everlasting consumers insight in markets. A strategic business move, here is why a high-quality sauce filling machine might just be one more step towards top rank contention.

Increase Production Speed

Meet High Demand Efficiently

The most logical reason you might have to buy a sauce filling machine is the tremendous boost in production speed it provides. Manual filling processes as it is not just slow but also leads to errors. A modern sauce filling machine, meanwhile, can fill from as little as 500 to over 5,000 bottles and hour depending on type. It's this fast throughput that enables you to satisfy demand, even during high-volume seasons like Christmas and without having the quality suffer.

Maintain Product Quality Across The Line

Uniformity in Every Bottle

Being consistent is vital in holding brand integrity and customer trust. A sauce filling machine allows you accurate dispense of the amount in each bottle- this helps not only with overall batch uniformity but goes lengths to help against false filing charges which can be quite a significant cost. In addition to improving how the product looks on shelves, this accuracy helps keep taste and texture consistent - which are factors that naturally come into play when dealing with customer satisfaction.

Reduce Wastage

Materials cost less, how much more profit?

Sauce filling machines work so that product waste is minimized. Colors On Food Safe BottlesAdvanced technologies during fillings through piston or overflow methods can dispense the correct sauce amount, avoiding spills and overfills. For businesses, that precision means less sauce wasted and more production cost savings. Less material waste; sustainability is a feature that consumers are beginning to care about.

Improve Hygiene Standards

Keep Your Production Tidy

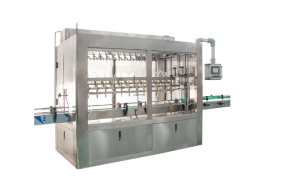

In the food processing sector, cleanliness tops everything. The sauce filling machines are made of materials that include; stainless steel, a material which is both long-lasting and very easy to clean. A vital specification to avoid pollution and adhere with food safety laws. Additionally, the automation these machines offer means that there is less contact with human hands on this sauce provided further sanitation.

Streamline Operations

Simplify Your Production Line

When you have a sauce filling machine as part of the production line, it will automate so many operations that there are few people who want to involve in bottling your products for hours. Automation takes the pressure off your staff making it easier for them to concentrate on other vital components of manufacturing production. Most modern fillers, in addition to being highly efficient with low breakages and easy cleaning/maintenance times are also quite simple to interface into your other line equipment (cappers & labelers) creating a more cohesive workflow.

Key Insights

In addition to the mechanical efficiency that a sauce filling machine in your business operations gives you (and is certainly important), there are other strategic advantages you now have: quality control, cost management and scalability. If you are a small artisan producer or a major commercial manufacturer, all that said your move to higher levels of automation in filling will have huge impact on the productivity and profit at your company. The up-front cost of this type of equipment sets your business on the road to growth and profit within a competitive world in food production.